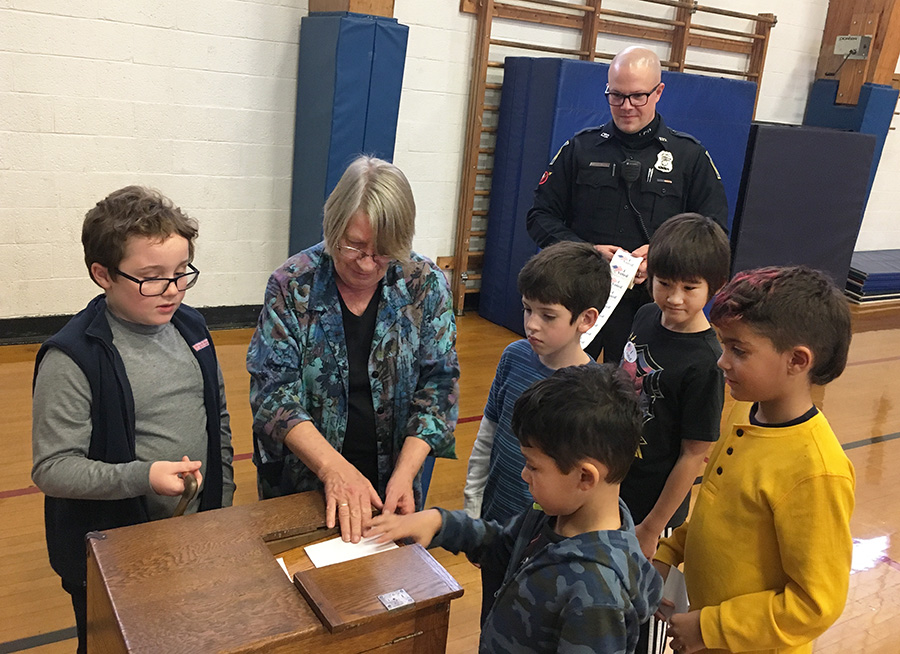

The GearTicks robotics team. Back row, left to right: Trevor Tsang, Anna Sander, Evan Lee, Jack Hutchinson, Wesley Lo, Ben Morris, Kevin Ji, Alex Payne, and Andreas Muzila. Middle/front row, left to right: Emily Appleby, Olivia Crisafi, Amelia Pilar, Howie Tsang, Irene Terpstra, Audrey Gammack, Ken Hawkey, and Prerna Karmacharya. All are Lincoln residents; Lee, Terpstra, and the Tsangs are L-S students, Hutchinson and Sander attend Concord Academy, and the others are Lincoln School students (click image to enlarge).

By Anna Sander, Prerna Karmacharya, and Evan Lee

A group of middle- and high school students from Lincoln has partnered with the Maker Club at the Perkins School for the Blind to make prosthetic hands using the Lincoln GearTicks’ 3D printer.

The GearTicks—the robotics team of students from the Lincoln School, Lincoln-Sudbury Regional High School and other schools—used their 3D printing, puzzle solving, and mechanical assembly skills to create low-cost prosthetic hands for children who aren’t able to afford more expensive prosthetics as they grow.

e-NABLE, which provides the designs for the hands, had its beginnings five years ago when founder Ivan Owen collaborated with a South African carpenter who had lost a finger in a woodworking accident. He ultimately developed a set of 3D-printable prosthetic hands and put the designs for them in the public domain so they can be printed and assembled by anyone with access to a 3D printer.

The GearTicks participate in FIRST Tech Challenge (FTC), an annual robotics competition whose mission to encourage students to enter robotics and other STEM-related fields. Although the competition involves designing, building, and programming robots, there’s also a focus on community outreach. After hearing about e-NABLE’s project, the team knew they wanted to become part of the global e-NABLE community of hand-builders that’s sprung up to help those who were born without fingers or lost them to due to injuries or disease.

The GearTicks got their first 3D printer, a Flashforge Creator, four years ago, and they were able to print most of the parts for their robot for the 2016-17 season. The machine uses plastic filaments to create a precise layered object based on a CAD (computer-aided design) file. The team now has a new Prusa i3 MK2 3D printer and is in the process of designing and printing for this season’s robot. With the help of GearTicks coach Anne Hutchinson, they even made this video starring and written by team members Anna Sander and Jack Hutchinson explaining how the team uses 3D printing.

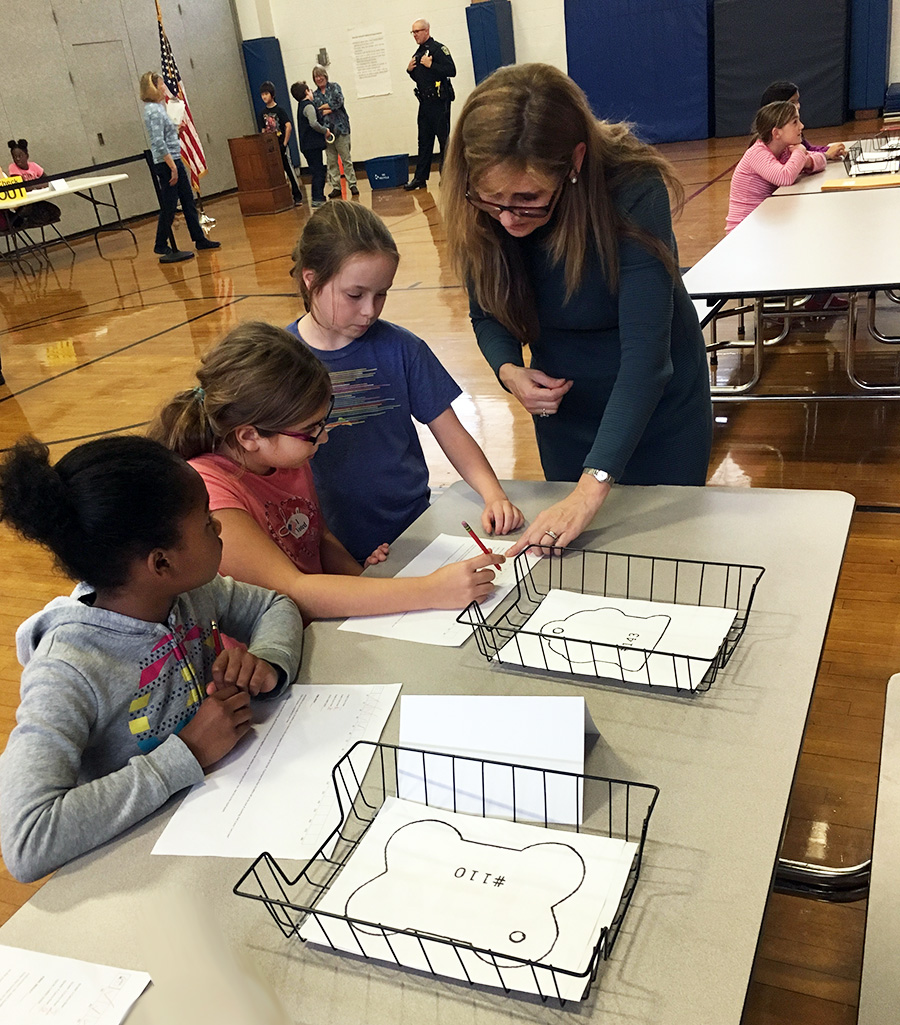

This fall, the GearTicks printed several sets of the e-NABLE hands. They used a plethora of colors, mixing and matching fingers, thumbs and various other joints to create colorful and unique hands to ship around the world. Eventually, they expanded the project to other outreach events, such as Boston Scientific’s Bring Your Child to Work Day and the Girl Scouts’ “Geek is Glam” Expo, where they worked with students on assembling the hands. At this year’s Boston Scientific event (which the GearTicks have been involved with every summer since 2015) they hosted about 300 kids over the course of six hours and worked with them to assemble hands, build Bristlebots, and teach them how to drive the GearTicks robot.

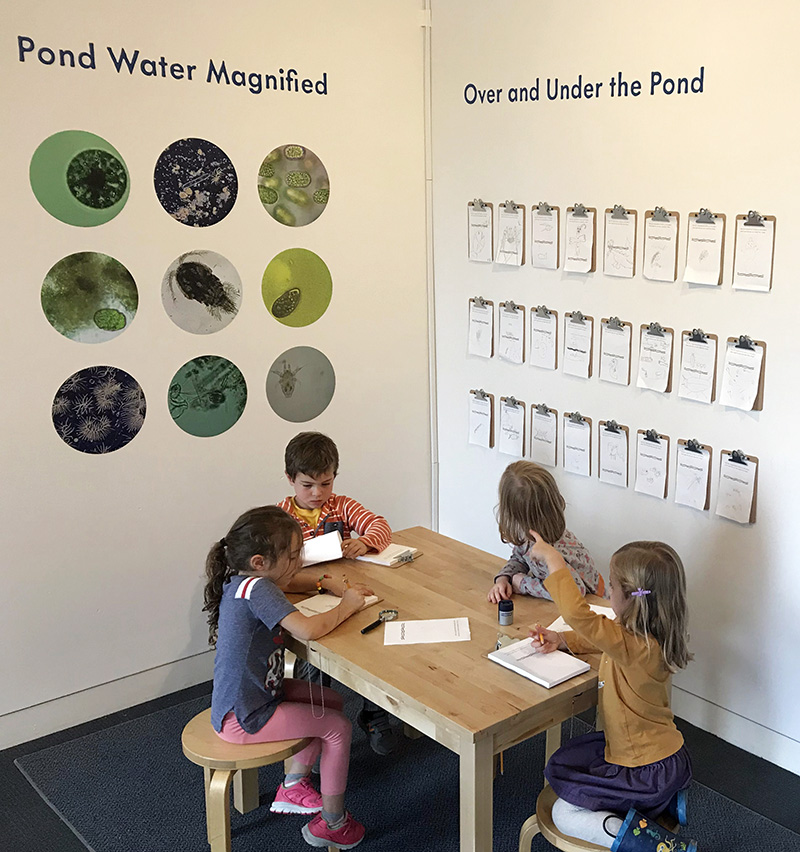

Most recently, the GearTicks partnered with the Perkins School’s Maker Club, which began as a group for visually impaired students interested in STEM-related opportunities beyond the classroom. The Lincoln students attended several of the club’s meetings, getting to know the Perkins students by working alongside them on their current projects. Later, the students split into mixed teams with each group receiving a kit of parts for one hand and all the necessary instructions to assemble it. Everyone got to work deciphering the assembly guide, and the sighted students helped the Perkins kids feel how the parts were supposed to fit together. Subsequent visits focused on creating the hands in these groups.

Natalie, a 21-year-old Perkins student, worked in a group with GearTicks members Evan Lee of L-S and Lincoln School eighth-grader Alex Payne. Pushing in the assembly pins for the hands was initially a challenge for her, but she and her group mates completed one full hand and half of a second. The kids also found that they had many common interests beyond engineering—everyone loved Spanish and music. By the third meeting, Natalie had learned the words for different colors and hand parts in Spanish.

Another Perkins student, CJ, worked with Jack Hutchinson, a student at Concord Academy. CJ, who really enjoys puzzles, immediately dove into the project. Despite not being able to see, he had a natural grasp of the project and required little instruction or help. “CJ was a really cool kid to work with. He was really talented with his hands, and I’m looking forward to seeing what he does in the future,” Hutchinson said.

Together, the groups assembled over 20 prosthetic hands. Despite coming from different backgrounds and abilities, all the students found a common passion for using their engineering skills for the benefit of their community. They’re hoping to meet one more time to package the hands and send them to kids who need them.

Other community service projects

In addition to the hands project, the GearTicks have been working on a Deer DeFence project for Minuteman National Historic Park. A landscape architect for the National Park Service contacted them last spring to see if they could design a fastener to support an enclosure to protect trees in the park’s orchards from hungry deer and goats. Over the summer and fall, they designed several iterations of the part and, after a few rounds of testing, recently installed these fasteners on about ten trees at Minuteman NHP.

The team also helped the Solarize Mass group of Lincoln, Sudbury, and Wayland by creating a sandwich board sign to promote awareness of solar power that required them to design a number of 3D printed parts.

“These projects have been a blast, and we’re always looking for more ways to get involved,” Sander said.